Why TPO Roof Installation Is the Go-To Choice for Today’s Commercial Roofs

TPO roof installation is now the dominant choice for commercial buildings across the United States, accounting for roughly 40% of the commercial roofing market. For Central Texas property owners comparing options on an energy-efficient, long-lasting system, TPO delivers a rare combination of performance, longevity, and value. Many building owners start by reviewing a trusted local provider’s commercial roofing and exterior services to understand how TPO fits into a complete building envelope strategy.

This single-ply membrane system combines energy efficiency, durability, and cost-effectiveness in a way that few other roofing materials can match.

Quick Answer: Essential Steps for TPO Roof Installation

- Prepare the roof deck – Clean, dry, and repair the substrate

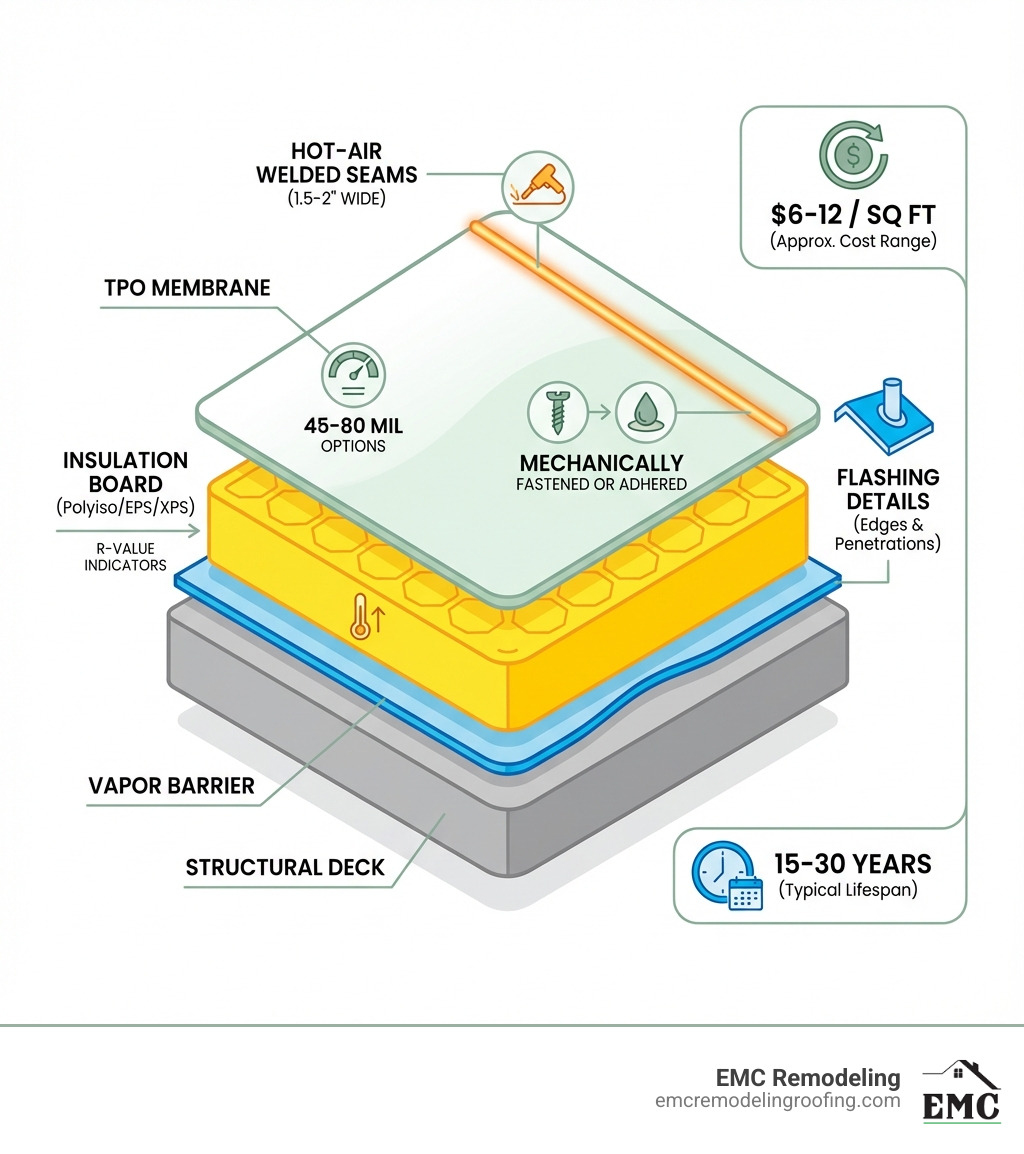

- Install insulation – Choose polyiso, EPS, or XPS based on R-value needs

- Lay the TPO membrane – Allow 20-30 minutes for material relaxation

- Choose fastening method – Mechanically attached, fully adhered, or ballasted

- Weld the seams – Use hot-air welding equipment at 500-600°F

- Install flashing – Seal all penetrations, walls, and roof edges

- Conduct final inspection – Probe seams and check for proper adhesion

Key Cost Range: $6-$12 per square foot (materials and labor, 2025 pricing)

Expected Lifespan: 15-30 years with proper installation and maintenance

If you’re considering a roof installation for your commercial property, understanding the TPO process helps you make informed decisions about your investment. Property managers who pair professional installation with a proactive roof repair and maintenance plan routinely achieve life cycles at the upper end of the 30-year range for TPO systems in hot-climate markets like Central Texas.

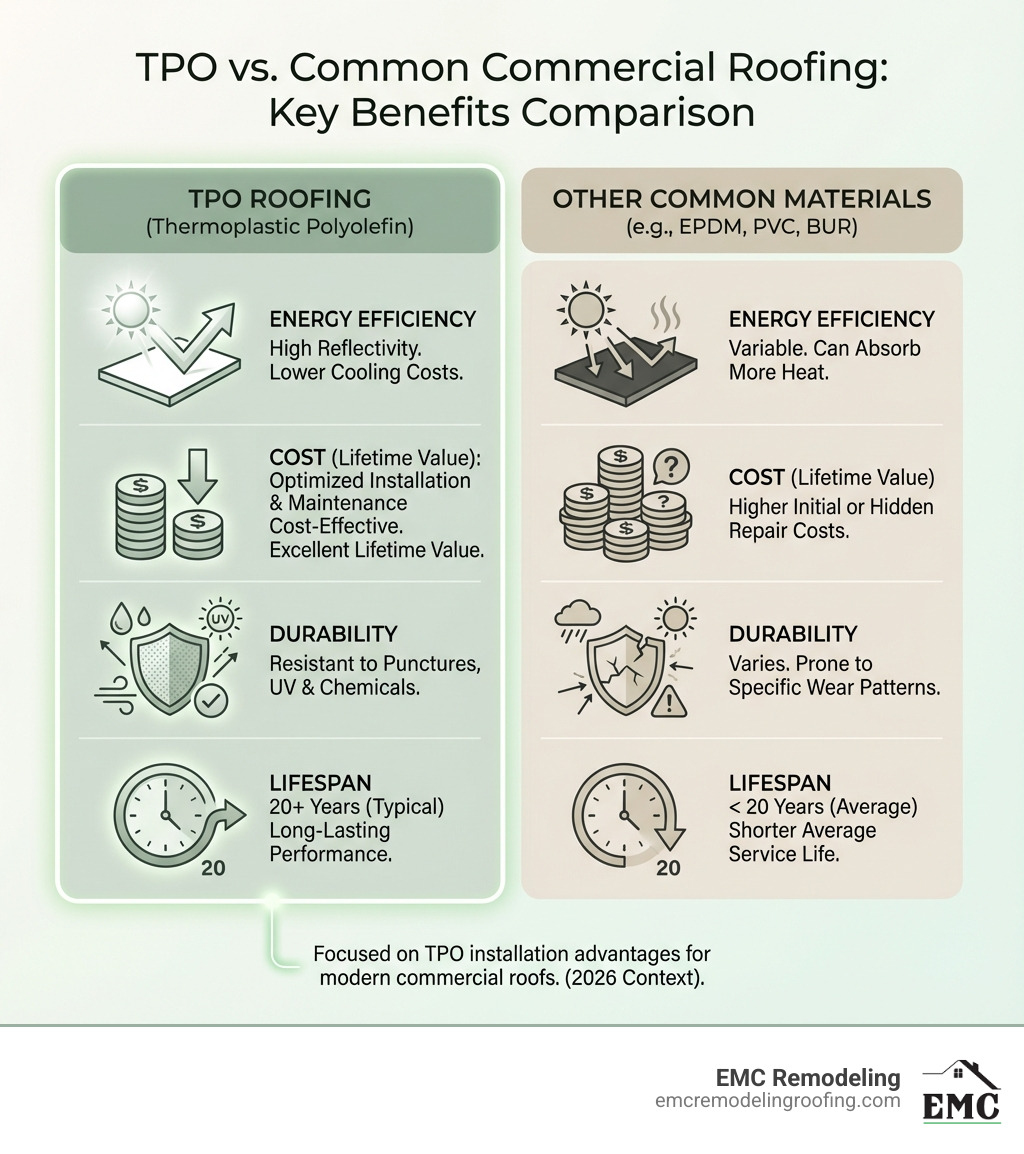

Why TPO stands out:

- Energy efficiency – White reflective surface reduces cooling costs by reflecting UV rays.

- Durability – Resists tears, punctures, and chemical exposure.

- Flexibility – Remains pliable in cold weather and heat-weldable for strong seams.

- Cost-effective – Lower installation costs compared to PVC while maintaining performance.

The thermoplastic polyolefin (TPO) membrane consists of a blend of polypropylene and ethylene-propylene rubber, reinforced with polyester fabric, giving it extreme pliability and excellent weldability.

As Matthew Runyon, President of EMC Remodeling & Roofing with over 15 years of experience, I’ve overseen numerous TPO roof installation projects across Central Texas, including fast-response replacements after hail and wind storms. Whether you’re dealing with a commercial roofing project in Cedar Park or exploring options for a durable commercial roof, this guide breaks down everything you need to know.

Pre-Installation Blueprint: Preparing for a Flawless TPO Roof

Meticulous preparation of the roof deck is paramount before any TPO membrane is laid. A properly prepared substrate ensures maximum adhesion, prevents future issues, and is the foundation for a long-lasting TPO system. This phase resolves underlying problems that could compromise the entire TPO roof installation.

Key Considerations for Roof Deck Preparation

Our goal is to create an ideal surface for your new TPO system. This involves several critical steps:

- Clean Surface: The roof deck must be impeccably clean, free of all debris, dust, dirt, oils, and other contaminants that can interfere with adhesive bonding or membrane welding.

- Dry Substrate: Moisture is the enemy of a roofing system. The deck must be completely dry before installation begins, as trapped moisture can lead to blisters and poor adhesion.

- Damage Repair: All existing damage to the roof deck, such as cracks, holes, or rot, must be repaired to create a smooth and sound substrate. Voids greater than ¼ inch wide should be filled.

- Structural Integrity: We assess the roof deck’s overall structural integrity, addressing any sagging or soft spots that indicate deeper issues before installing a new roof.

- Removing Old Roofing Material: A complete tear-off of the old roofing system is often required to inspect the structural deck properly. However, some TPO systems can be installed over existing roofs if the substrate is stable and dry.

Choosing the Right Insulation for Your TPO System

Insulation provides thermal resistance (R-value) and a smooth, stable surface for the membrane. The right choice is crucial for performance and longevity.

- Insulation R-value: The R-value measures thermal resistance; a higher R-value means better insulation and lower energy costs, a vital consideration for businesses in Central Texas.

- Tapered Insulation Systems: For low-slope roofs, tapered insulation boards are essential for creating a positive slope to prevent ponding water. The International Building Code® 2018 Edition prescribes a ¼:12 minimum slope for new thermoplastic single-ply construction.

- Compressive Strength: Insulation must withstand foot traffic and equipment loads without compressing, which could create depressions and lead to ponding water.

Common types of insulation compatible with TPO roofing systems:

- Polyisocyanurate (Polyiso): A popular choice for its high R-value per inch, excellent fire resistance, and good compressive strength. Its energy savings can offset a higher upfront cost.

- Expanded Polystyrene (EPS): Offers a good R-value and is lightweight and cost-effective, providing the “highest R-value per dollar.” It typically requires a cover board for direct TPO adhesion.

- Extruded Polystyrene (XPS): Has a higher R-value and better moisture resistance than EPS. Like EPS, it generally requires a cover board for TPO applications.

For more insights into optimizing your commercial roof, consult our Commercial Roofing Cedar Park TX Guide.

The Core Process: A Step-by-Step Guide to TPO Roof Installation

Once the roof deck is prepared and insulation is installed, we begin laying and securing the TPO membrane. This process transforms the deck into a durable, watertight, and energy-efficient roofing system through careful planning and specialized equipment.

Step 1: Choosing Your TPO Fastening Method

The method used to secure the TPO membrane impacts performance, longevity, and cost.

- Mechanically Fastened Systems: A common and cost-effective method where the TPO membrane is secured with specialized fasteners and plates in the seam areas. The next sheet is welded over them, concealing the fasteners. This system offers excellent wind uplift resistance and is quick to install.

- Fully Adhered Systems: The TPO membrane is glued directly to the substrate with a strong bonding adhesive. This creates a smooth, aesthetic surface with superior wind uplift resistance, ideal for complex roof shapes. It is more labor-intensive and requires specific weather conditions for installation.

- Ballasted Systems: The TPO membrane is loosely laid and held in place with a layer of ballast (gravel or pavers). This simple, cost-effective method offers excellent wind uplift resistance but is only suitable for roofs that can support the significant added weight (minimum 1000 lbs/SQ).

Step 2: Proper TPO Roof Installation and Seaming

Membrane sheets are unrolled and allowed to relax for 20-30 minutes to minimize wrinkles. Sheets are typically laid perpendicular to the roof slope with a minimum 6-inch overlap to ensure a watertight seal.

- Hot-Air Welding: This is the hallmark of TPO installation. Specialized equipment melts the overlapping sheets, fusing them into a monolithic, watertight bond stronger than the membrane itself. We use automated welding robots for long seams and hand welders for details.

- Seam Integrity: Immediately after welding, a silicone roller applies pressure to create a continuous bond. After cooling, every inch of the seam is probed with a dull tool to check for imperfections that could cause leaks.

- T-Joint Patches: At intersections where three sheets meet, reinforced T-joint patches are welded over the area to provide additional strength and ensure a watertight seal.

Proper TPO installation is a science. For a deeper dive into professional techniques, you can Learn how to install TPO roofing like a professional roofer.

Step 3: The Critical Role of Flashing in a TPO Roof Installation

Flashing is the most critical component for preventing water intrusion at vulnerable points.

- Penetrations: Vents, pipes, skylights, and HVAC units require precise flashing. We use pre-molded TPO accessories like pipe boots that are heat-welded to the membrane for a seamless seal.

- Walls and Curbs: At changes in the roof plane, such as parapet walls or equipment curbs, the TPO membrane is extended up the vertical surface (minimum 8 inches) and securely attached.

- Termination Bars: At the top edge of vertical flashing, a metal termination bar is mechanically fastened to the wall, holding the membrane firmly. A continuous bead of sealant is applied along the top edge to prevent water from getting behind the flashing.

Avoiding Pitfalls: Common Mistakes and Pro-Level Solutions

Even with the best materials, a TPO roof installation can fail if common mistakes are made. As experienced roofing contractors serving communities like Lago Vista and Leander, we know how to prevent these pitfalls to ensure a long-lasting TPO roof.

- Improper Surface Preparation:

- Mistake: Installing TPO over a dirty, damp, or uneven substrate, leading to poor adhesion, blisters, and premature failure.

- Solution: Ensure the roof deck is clean, dry, and smooth. All damage must be repaired and voids filled before installation begins.

- Incorrect Fastening:

- Mistake: Using too few or incorrect fasteners, or applying insufficient adhesive, compromising wind uplift resistance.

- Solution: Strictly follow manufacturer guidelines for fastener patterns and adhesive application based on wind uplift requirements.

- Poor Seaming:

- Mistake: Inconsistent heat welding, creating “cold welds” or “fish mouths” that are prime entry points for water.

- Solution: Calibrate welding equipment daily, perform test welds, and probe every inch of every seam after it cools to identify and repair any imperfections.

- Neglecting Flashing:

- Mistake: Rushing flashing details around penetrations and edges, which are the most common sources of leaks.

- Solution: Treat flashing as the most critical step. Use pre-molded accessories, ensure the membrane extends sufficiently up vertical surfaces (min. 8 inches), and secure with termination bars and sealant.

- Wrinkles and Blisters:

- Mistake: Failing to let the TPO membrane relax before attachment or trapping moisture/solvents during adhesive application.

- Solution: Always allow TPO sheets to relax for 20-30 minutes. Ensure the substrate is dry and adhesives have properly “flashed off” before mating the membrane.

- Insufficient Inspections:

- Mistake: Only performing a final walk-through after the job is complete.

- Solution: Conduct daily inspections of seam quality, fastener placement, and flashing details as work progresses to address issues immediately.

A professional roofing contractor understands these nuances. For more guidance on selecting an expert, refer to our Roofing Contractor Ultimate Guide.

After the Install: Costs, Maintenance, and Emergency Repairs

Once your new TPO roof is installed, understanding the costs, maintenance, and repair options will help you maximize its 15 to 30-year lifespan.

What Influences TPO Roof Installation Costs?

While TPO is cost-effective, the final price varies. As of 2025, expect a range of $6 – $12 per square foot. Key factors include:

- Project Size and Complexity: Larger, simpler roofs have a lower per-square-foot cost than smaller or more complex roofs with numerous penetrations.

- Existing Roof Condition: A full tear-off of the old roof adds to the cost compared to a re-cover, which is only possible if the existing substrate is in good condition.

- Membrane Thickness: Thicker membranes (60-mil, 80-mil) offer greater durability and longer warranties at a higher material cost than standard 45-mil.

- Fastening Method: Fully adhered systems are often more labor-intensive and costly than mechanically fastened systems.

- Insulation: The type (Polyiso, EPS, XPS), R-value, and use of a tapered system will impact material costs.

- Warranty: Longer manufacturer warranties often require specific materials and inspections, increasing the upfront cost.

Recommended Maintenance for TPO Roofing

Regular maintenance is key to achieving a 30-year lifespan. We recommend biannual inspections (spring and fall) and checks after severe weather.

- Debris Removal: Keep the roof surface, drains, and scuppers clear of leaves, branches, and dirt to prevent blockages and ponding water.

- Seam and Flashing Inspection: Check all heat-welded seams and flashing around penetrations for any signs of separation, cracking, or damage.

- Address Ponding Water: If water remains on the roof for more than 48 hours after rain, it indicates a drainage problem that requires immediate attention.

Explore our comprehensive Roofing Services for maintenance and inspection plans.

Repairing Existing TPO Roofs

Even durable TPO roofs may need repairs. The correct approach depends on the saturation level of the underlying insulation, which we detect using infrared inspections.

- If Less Than 25% Saturation: Spot repairs (patching) or applying a silicone restoration membrane can extend the roof’s life by 10-20 years. A silicone coating is a liquid-applied layer that creates a new, seamless waterproof surface over the existing TPO.

- If More Than 25% Saturation: A complete tear-off and replacement is the only viable long-term solution. Attempting to re-cover a roof with extensive wet insulation will lead to continued structural problems and wasted money.

Emergency Roof Repair and 24/7 Support

Sudden leaks, storm damage, or unexpected failures demand immediate action to protect your assets. We provide 24/7 emergency roof repair services for commercial properties across Temple, Killeen, Georgetown, and our other Central Texas service areas. Our rapid response team is always ready to secure your property, mitigate damage, and implement urgent repairs, reinforcing our commitment to being your trusted local roofing partner when you need it most.

Conclusion: Protect Your TPO Roof Investment with Expert, 24/7 Support

TPO roof installation delivers a proven combination of energy efficiency, durability, and cost-effectiveness, which is why it is the leading single-ply choice for commercial buildings in the United States and throughout Central Texas. Its highly reflective surface can reduce cooling loads by double-digit percentages in hot climates, while robust, heat-welded seams create a continuous watertight barrier that performs reliably under intense UV, wind, and hail exposure.

However, the long-term performance of any TPO roofing system depends entirely on professional installation and disciplined maintenance. The detailed steps involved—from rigorous deck preparation and correct insulation selection to calibrated heat welding, watertight flashing, and methodical inspections—require an experienced crew that understands local building codes, wind uplift zones, and emergency response protocols. Skipping these professional standards often leads to seam failure, ponding water, and expensive leak damage that far exceeds any initial cost savings.

At EMC Remodeling, we combine manufacturer-approved installation practices with direct owner involvement on every project. As a family-operated roofing company serving Temple, Killeen, Belton, Lago Vista, Cedar Park, Leander, Georgetown, Pflugerville, and Salado, we understand the unique storm, hail, and heat stresses your commercial roof faces. Our team provides full lifecycle support—from new TPO roof installation to preventive roof repair and maintenance services, leak investigations, and emergency dry-in after severe weather.

If your facility is located in a high-exposure corridor like I-35 or SH-130, partnering with a local specialist is especially critical. Business owners in Killeen, for example, can work directly with our nearby crew through our dedicated roofer near me in Killeen, TX service page for rapid assessment and deployment.

For a professional assessment or to schedule your TPO roof installation, contact our team today. Our 24/7 emergency response line ensures you can reach a qualified roofing expert any time a leak, blow-off, or storm event threatens your operations, so your building stays protected and your business stays open.