Why a Strong Garage Roof Matters More Than You Think

As a trusted Central Texas roofing expert, EMC Remodeling knows that a solid garage roof is essential for protecting your vehicles, tools, and valuables. A failing roof not only puts your belongings at risk but can also lower your home’s appeal to buyers. In fact, research shows that adding a garage space can increase your property value by up to 5%. If you’re considering a garage roof upgrade, start by exploring our roofing solutions for homeowners to ensure you make the best investment for your property.

Corrugated garage roof replacement is essential when your roof shows signs of rust, leaks, or structural damage. Here’s what you need to know:

Key Replacement Indicators:

- Visible rust or corrosion on metal sheets

- Water stains or active leaks inside the garage

- Peeling paint or coating deterioration

- Roof age over 25-40 years

- Loose or missing fasteners

Popular Material Options:

- Metal sheets: 40-70 year lifespan, weather-resistant

- Polycarbonate panels: Lightweight, UV-filtering, 15-20 years

- Bitumen sheets: Affordable, sound-dampening, 20+ years

Average Costs: Costs for a corrugated garage roof replacement vary based on the size of your garage, material choice, and local labor rates.

Whether you’re dealing with a leaking corrugated metal roof or planning an upgrade, the right materials and installation make all the difference. Our team knows that Central Texas weather demands durable solutions that can handle intense sun, sudden storms, and temperature swings. We specialize in both metal and alternative roofing solutions that stand up to our challenging climate.

5 Signs It’s Time to Replace Your Corrugated Garage Roof

Your garage roof works hard every single day, standing guard against Central Texas weather that can swing from scorching heat to sudden hailstorms. But even the toughest corrugated roofs eventually wave the white flag. The trick is catching the signs early, before a small problem turns into a wallet-draining disaster.

Think of your roof like an old pickup truck—it might run fine for years, but ignore that strange rattling sound, and you’ll end up stranded on the highway. A thorough inspection can confirm the extent of the damage, so don’t wait until small issues become costly repairs.

Here’s what to watch for when evaluating whether you need a corrugated garage roof replacement:

Visible damage is often your first clue that trouble’s brewing. Peeling paint, chipped coatings, or general material breakdown might seem cosmetic, but they’re actually your roof’s protective armor failing. Once that protection is gone, the elements start winning the battle.

Leaks and water stains are the most urgent red flags. If you’re seeing drips during rainstorms or notice those telltale brown stains on your garage ceiling, your roof is already failing. Even a single leak can lead to mold growth, wood rot, and damage to everything you’ve stored in there. Multiple leaks? That’s your roof telling you it’s time for retirement.

Widespread rust or corrosion spells trouble for metal corrugated roofs. Rust typically starts when the protective coating wears off, exposing bare metal to moisture and oxygen. While galvanized coatings help resist corrosion, they’re not invincible—especially after decades of Central Texas sun and storms. If rust has spread beyond just a few spots, the structural integrity of your entire roof is compromised.

Age matters more than you might think. Even if your roof looks decent from the ground, time takes its toll. Corrugated metal roofs can last an impressive 40 to 70 years with proper maintenance, but other materials have shorter lifespans—polycarbonate and fiberglass typically last 15-20 years, while bitumen sheets give you about 20+ years. If your garage roof is approaching or has passed its expected lifespan, it’s living on borrowed time.

Peeling paint or coating deterioration might look like a simple maintenance issue, but it’s actually a warning sign. These protective layers don’t just make your roof look good—they’re essential for preventing rust, UV damage, and water infiltration. Once they start failing, the underlying material becomes vulnerable to all the elements Central Texas can throw at it.

How to Spot Critical Damage

When you’re inspecting your garage roof, some damage jumps out at you, while other problems hide in plain sight. Cracks in corrugated sheets create direct pathways for water, while holes—whether from hail damage or wear—are obvious trouble spots that need immediate attention.

Dents from hail might seem harmless, but they can create low spots where water pools instead of running off properly. Over time, this standing water leads to rust and eventual failure. Loose fasteners are particularly sneaky—they might look fine from below, but a loose screw can allow wind to get under the roofing material, potentially tearing off entire sections during the next big storm.

Sagging sections are perhaps the most serious warning sign. When your corrugated roof starts to sag, it means the underlying structure is failing, the roofing material has lost its strength, or both. This isn’t something you can patch up with a tube of caulk—sagging sections require immediate professional attention to prevent complete failure.

The Hidden Danger of Asbestos in Older Roofs

Here’s something that might surprise you: if your garage was built before the late 1980s, there’s a real possibility that those older cement sheets contain asbestos. Back in the day, asbestos was the wonder material—durable, fire-resistant, and seemingly perfect for roofing applications.

Unfortunately, we now understand the serious health risks that come with disturbed asbestos fibers. When these microscopic fibers become airborne and are inhaled, they can cause severe respiratory problems and other serious health issues decades later.

If you suspect your existing roof contains asbestos (it often looks like grey, fibrous cement sheets), don’t even think about tackling removal yourself. Professional testing is the only way to know for sure what you’re dealing with. If asbestos is confirmed, safe removal procedures must be followed by certified professionals who have the proper equipment and training.

This isn’t a place to cut corners or try to save money. The EPA provides detailed guidance on asbestos safety, and we always follow their protocols when dealing with potentially hazardous materials. Your family’s health is worth far more than any savings from a DIY approach.

Section 2: Choosing the Best Corrugated Roofing Material for Your Garage

Selecting the right material for your corrugated garage roof replacement can feel overwhelming with all the options available. Think of it like choosing a car—you want something that fits your budget, meets your needs, and won’t leave you stranded in a few years. The good news? We’ve helped hundreds of Central Texas homeowners steer this decision, and I’m here to break down your best options.

Your choice ultimately comes down to three main factors: how long you want it to last, what you’re willing to spend upfront, and how much maintenance you want to deal with. Let’s explore each material type so you can make the best decision for your specific situation.

| Material Type | Lifespan | Cost (Relative) | Durability | Maintenance | Key Considerations |

|---|---|---|---|---|---|

| Metal Roofing | 40-70 years | $$$ | Excellent | Low (inspections, cleaning, fastener checks) | Can be noisy in rain; Prone to denting with softer metals; Excellent weather resistance; Recyclable; Can increase property value. |

| Polycarbonate/Fiberglass | 15-20 years | $$ | Good (can become brittle) | Low (cleaning) | Lightweight; Allows natural light; UV filtering; DIY-friendly; Can fade/become brittle over time; Less impact resistant than metal. |

| Bitumen Sheets | 20+ years | $ | Good | Low (virtually maintenance-free initially) | Affordable; Lightweight; Noise-reducing; UV-resistant; Made from recycled materials; Can fade in intense sun; Requires good sub-deck. |

Metal Roofing (Steel & Aluminum)

If you’re looking for the gold standard in garage roofing, metal is your champion. We’ve installed metal roofs that are still going strong after 50+ years—that’s longer than most mortgages! When properly maintained, these roofs can last anywhere from 40 to 70 years, making them an investment that truly pays for itself over time.

The beauty of metal roofing lies in its incredible versatility and strength. The corrugated profile isn’t just for looks—it creates natural ridges that channel water away efficiently while adding structural integrity without extra weight. We’ve seen these roofs weather everything Central Texas can throw at them, from baseball-sized hail to those sudden summer storms that seem to come out of nowhere.

Metal roofs are incredibly weather-resistant, especially when they’re galvanized or properly coated. They’re also fire-resistant, which gives many homeowners extra peace of mind. Plus, if you’re environmentally conscious, you’ll love that many metal roofs contain recycled content and can be fully recycled at the end of their lifespan.

Here’s something that might surprise you: metal roofs can actually boost your property value. They’re seen as a premium upgrade that signals quality and longevity to potential buyers. Available in a wide range of colors and profiles, they can complement virtually any home style.

Now, let’s talk about the elephant in the room—noise. Yes, metal roofs can be louder during rainstorms, but it’s not the drumming symphony some people imagine. With proper insulation or underlayment, the sound difference becomes minimal. Many of our customers actually enjoy the gentle patter of rain on their metal roof!

One consideration with softer metals like aluminum is their susceptibility to denting from severe hail or falling branches. However, choosing the right gauge and material for your specific location minimizes this risk significantly.

Metal roofs are a top choice for longevity and protection, offering best durability that makes them worth every penny.

Polycarbonate & Fiberglass Sheets

These translucent options shine when you need natural light in your garage workspace. If you’re a weekend warrior who spends time tinkering with projects, or if your garage doubles as a workshop, these materials can transform a dark space into a bright, welcoming area.

The lightweight nature of polycarbonate and fiberglass sheets makes them incredibly DIY-friendly. They’re much easier to handle than heavy metal sheets, and installation is generally straightforward for handy homeowners. Many of these materials also filter harmful UV rays while still letting beneficial light through.

Cost-wise, they’re easier on the wallet than metal options, making them attractive for budget-conscious projects. However, there’s a trade-off in longevity—expect about 15 to 20 years of service life before they start showing their age.

The main challenge with these materials is that they can become brittle over time, especially with our intense Texas sun and temperature swings. They’re also less impact-resistant than metal, so a severe hailstorm could cause cracking or shattering.

Bitumen Roofing Sheets

Don’t overlook bitumen sheets—they’re the unsung heroes of garage roofing! These affordable, practical sheets offer excellent value for homeowners who want quality without breaking the bank.

What makes bitumen special is its natural sound-dampening properties. While metal roofs can amplify rain sounds, bitumen sheets actually quiet them down. They’re also surprisingly durable despite their budget-friendly price tag, and many contain up to 50% recycled materials.

Installation is refreshingly simple—they’re lightweight, easy to cut, and forgiving to work with. You can even walk on them (with a crawl board to spread the load) during installation. They work on roof pitches as low as 5 degrees, giving you flexibility in garage design.

The main trade-off is aesthetics and some fading over time with intense sun exposure. They require a solid deck or wooden battens underneath, but that’s standard for most roofing projects anyway.

For many homeowners, bitumen sheets hit the sweet spot of affordability, durability, and ease of installation—making them a smart choice for practical garage roof replacements.

Section 3: Step-by-Step Guide to Corrugated Garage Roof Replacement

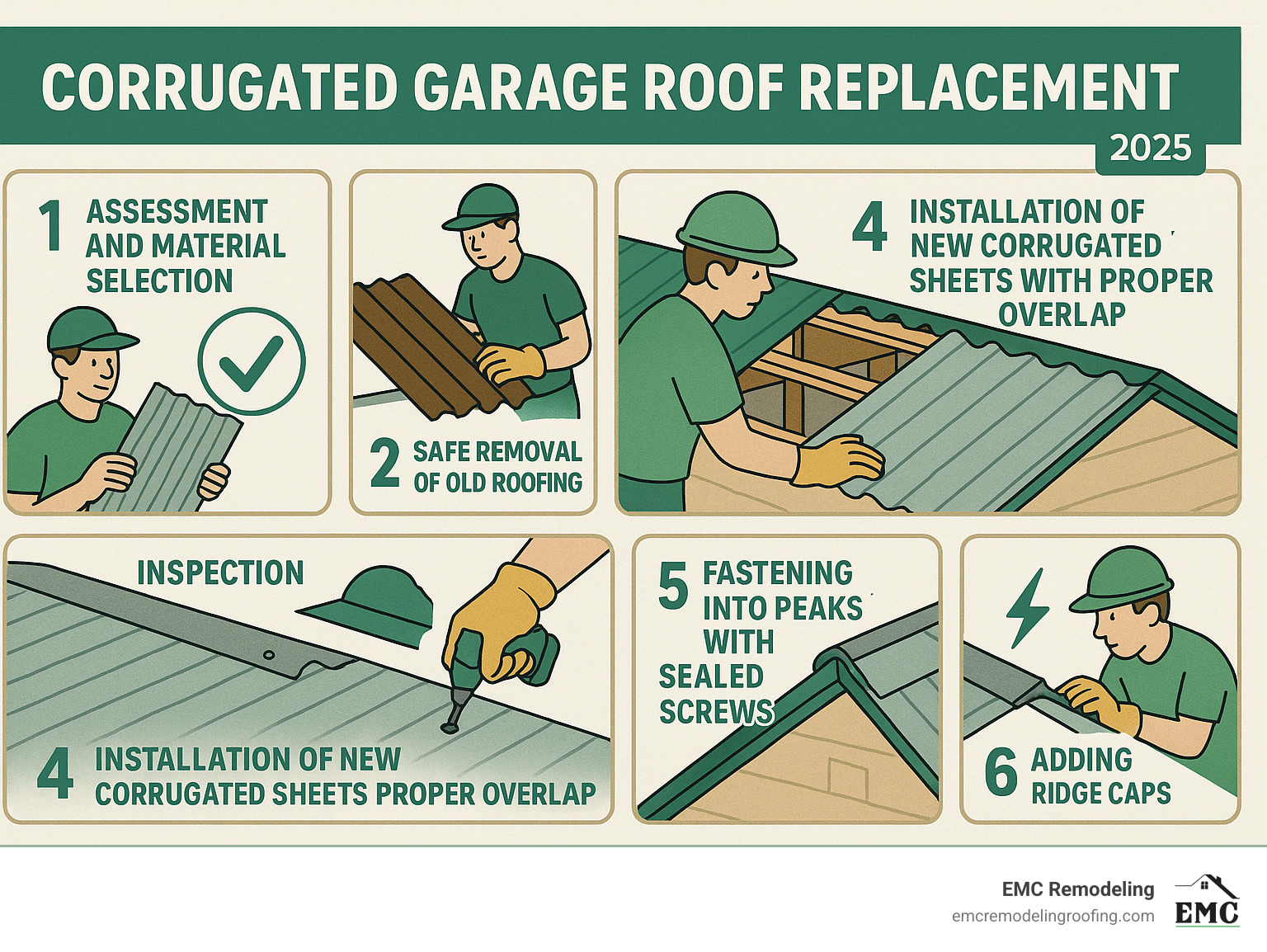

Whether you’re a DIY enthusiast or prefer professional help, understanding the process ensures a successful project. We believe in transparency, so here’s exactly how we approach a corrugated garage roof replacement at EMC Remodeling. For guaranteed quality and peace of mind, consider our roof replacement service.

The truth is, a roof replacement can feel overwhelming—but it doesn’t have to be! When you break it down into manageable steps, the process becomes much more approachable. We’ve guided hundreds of Central Texas homeowners through this journey, and we’re here to walk you through every detail.

Step 1: Preparation and Safe Removal of the Old Roof

Safety always comes first in our book—no shortcuts, no exceptions! Before any work begins, we take critical steps to ensure everyone stays safe and the project runs smoothly.

Personal protective equipment is absolutely non-negotiable. We always wear sturdy work gloves because metal sheets can have razor-sharp edges that’ll surprise you. Safety goggles protect your eyes from debris, while long sleeves and non-slip footwear are essential. If you’re working at height (which you likely are), fall protection gear becomes a lifesaver—literally.

Tool preparation makes the difference between a smooth project and a frustrating day. You’ll need pry bars, drills with the right bit sizes, tin snips or metal shears, a reliable tape measure, chalk line, utility knife, and a sturdy ladder. Having everything ready before you start saves countless trips up and down that ladder.

Weather timing can make or break your project. We always choose dry, calm days because wind can turn large sheets into dangerous sails, and rain creates slippery surfaces that nobody wants to deal with. Trust us—waiting for good weather is always worth it.

Debris disposal needs planning ahead of time. This might mean renting a dumpster or arranging transport to your local waste facility. Old roofing materials are heavy and bulky, so don’t underestimate this step.

Asbestos precautions are crucial for older garages. If you suspect asbestos in your existing roof, stop immediately and contact professionals for testing and removal. This isn’t a DIY situation—your health is too important to risk.

The removal process itself starts from the ridge and works down toward the eaves. We carefully pry up fasteners and gently lift old sheets, always watching for loose debris and sharp edges. If you’re replacing an existing corrugated roof, pay attention to how the old sheets were overlapped and fastened—it’s like getting a blueprint for your new installation.

Step 2: Installing Your New Corrugated Garage Roof

Once the old roof is gone and the underlying structure is ready, it’s time for the exciting part: installing your new, durable corrugated roof!

Structural inspection is your foundation for success. With the old roof removed, you have a clear view of the underlying purlins or roof deck. We inspect every inch for signs of rot, damage, or weakness. Any compromised wood gets replaced with pressure-treated lumber to ensure a rock-solid foundation. All purlins must be securely anchored—this isn’t the place to cut corners.

Underlayment installation might seem optional, but we recommend it for added protection. A synthetic roofing underlayment over your purlins or deck provides an extra barrier against moisture and helps with sound dampening, especially important for metal roofs. Think of it as insurance for your investment.

Sheet alignment and overlapping requires precision and patience. Corrugated sheets are designed to overlap, and getting this right is crucial for water shedding. For metal sheets, we typically use a two-rib overlap for optimal protection. For bitumen sheets, we ensure they’re laid opposite to the prevailing wind direction. Starting from one end of the roof, every sheet must be perfectly square with the eaves—small mistakes here become big problems later.

Proper fastening techniques are absolutely critical for longevity and leak prevention. Here’s where many DIY projects go wrong, so pay close attention. Always screw into peaks, not valleys—this is the golden rule for most corrugated metal and plastic sheets. The peaks are the raised parts of the corrugation, and fastening here allows water to flow freely in the valleys while putting less stress on the screw seals.

We use specialized roofing screws with rubber washers that compress to create watertight seals. Consistent spacing matters too—screws go in every 12-18 inches along the purlins, plus at overlaps and ridges. Don’t forget the overhang—sheets should extend slightly beyond the gutter line for proper water runoff.

Flashing and ridge cap installation completes your waterproof system. Flashing is your best friend around roof penetrations like vents and where the roof meets walls. Ridge caps cover the peak, providing both a watertight seal and a finished appearance. We always use quality sealant like butyl tape in all laps and under flashings—it’s the difference between a good job and a great one.

Step 3: DIY vs. Hiring a Central Texas Pro

Deciding whether to tackle a corrugated garage roof replacement yourself or hire professionals is one of the biggest decisions you’ll make. We’ve seen both approaches work, but the choice depends on several important factors.

DIY installation can offer significant cost savings, sometimes cutting your total project expense by 40-60%. There’s also real satisfaction in completing the work yourself—many of our customers tell us they’re proud every time they look at their garage. You control the timeline and can work at your own pace, which appeals to many homeowners.

However, DIY challenges are real and shouldn’t be underestimated. The time investment is substantial—what takes our crew a day might take a weekend warrior several weekends. Physical risks include working at height with heavy, sharp materials. Tool requirements can add unexpected costs, and permit navigation varies by location. Most importantly, warranty concerns arise because many material manufacturers require professional installation for full coverage.

Professional installation brings expertise and experience that’s hard to match. We’ve handled every type of roof challenge Central Texas can throw at us. Safety protocols are second nature, and we carry full insurance coverage. Warranty protection extends to both materials and workmanship, giving you complete peace of mind. Time efficiency means your roof gets completed quickly and correctly the first time.

The cost consideration for professional installation includes labor, but we often get better material pricing and can spot potential problems before they become expensive surprises.

For a hassle-free and guaranteed result, professional installation is our recommendation. When you consider the complexity, safety risks, and long-term implications, having experienced professionals handle your corrugated garage roof replacement often proves to be the wisest investment.

EMC Remodeling

5100 Midway Dr Suite 211, Temple, TX 76502